RPL’s Paper Standards

Paper is the backbone of Corrugation packaging. Paper quality can double the production of corrugated boxes or decrease production to half. This blog will explain the standards, challenges, and types of paper for the paper vendors of Roshan Packages Ltd. We have done extensive R&D in the last two decades to set the proper standards for the incoming paper. We also employ an extensive list of standards for the incoming paper at RPL.

We perform the following tests on the incoming Paper at Roshan Packages Ltd;

- Grammage check (g/m2)

- Caliper test(micron)

- Moisture (%)

- Ash (%)

- Bursting Strength (kg/cm2)

- RCT MD (KG)

- RCT CD (KG)

- Cobb(g/m2)

Grammage check on the lab is done by digital weigh scale. This test ensures that the supplier has provided us with the right paper grammage—non-uniform grammage affects the strength of the corrugated box.

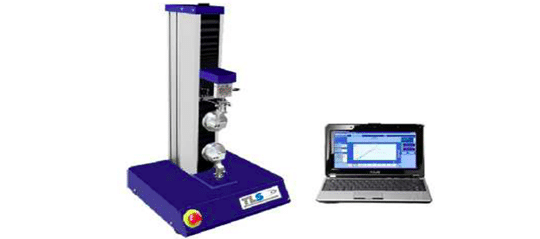

Bursting is the key to the strength of packaging. It shows the maximum pressure a paper can withstand before it raptures. We insert pressure in a perpendicular direction to the paper until it raptures. Bursting values varies according to paper quality. The Bursting value depends on the bonding forces as well as on the strength and fiber of the paper.

Furthermore, ash content is an ongoing concern for packaging companies. It not only impacts packaging quality but also damages critical machinery parts such as corrugating rolls. Ash content decreases the fiber content in the paper, reducing the paper strength. It decreases the paper thickness as well as reduces the paper smoothness.

Next on our testing list is moisture percentage in upcoming papers. Higher moisture percentage will result in lower ECT (Edge Crush Test) and BCT (Box Compression Test). Higher moisture content can cause bubbling and warpage in corrugated sheets, and this will also cause misprinting on corrugated sheets.

A Cobb Test is used to examine the amount of water absorbed by the incoming paper. A set time period is used to test the water absorption in the paper. This characteristic helps us plan a suitable combination of paper according to customer product. In the case of high Cobb values, our paper will absorb a high amount of water and reduce its strength. In some cases, liner paper even separates itself from inner fluting, resulting in box breakdown.

The Ring Crush test determines the edge-wise compression on the incoming paper. This test examines the tension of the paper. In this test, we determine percentage elongation at maximum force for the incoming paper before it breaks. This test is done in Machine Direction and Cross Direction.

Paper caliper varies according to different qualities of paper, and if the paper caliper diverts from standards, it will affect the corrugated sheet durability.

We are working round the clock with the capability of consuming more than 200 tons of paper in a day, so here is the golden chance for our vendors to increase their business with RPL.

-Haseeb Qausim, Engineer, Roshan Packages Limited